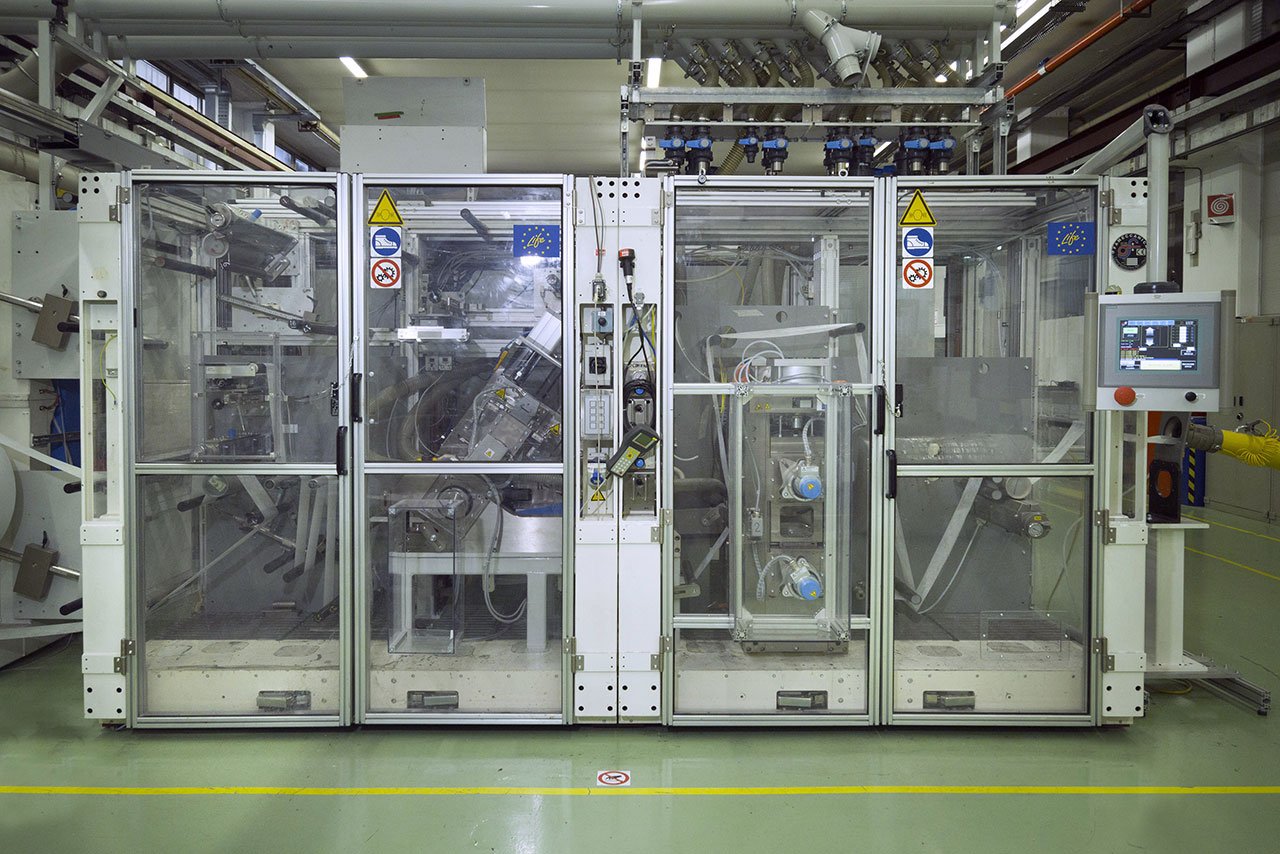

FAMECCANICA, coordinator of the LIFE ALL-IN project, dedicates a complete test stand to the web transformation action, with the installation of 2 units: 2D perforation and 3D perforation.

Holex-in is the Fameccanica patent solution for the in-line perforation of nonwoven material.

Perforated nonwoven is a feature that is more common in Asian markets where is present in most of the products as premade layer. With the in line perforation process Fameccanica can offer many advantages in terms of:

Perforated nonwoven is a feature that is more common in Asian markets where is present in most of the products as premade layer. With the in line perforation process Fameccanica can offer many advantages in terms of:

Fameccanica also developed the in-line vision system to check results of the perforation process, in terms of number of holes and holes dimensions

Test and next steps

The process has been tested at full speed (450 m/min). A long run of 24 hours has been done to validate the process stability. The phased process has been tested and validated

The development of the 3D perforation process of the sheets aims to create product layers with funnel-shaped holes oriented in a specific direction.

This allows to obtain good fluid handling benefit. This kind of raw material is already used in hygiene products and FAMECCANICA is already processing this type of premade NW in its line. The in line creation of this kind of product will give environmental impact reduction and product/process benefit in comparison with standard product.

This allows to obtain good fluid handling benefit. This kind of raw material is already used in hygiene products and FAMECCANICA is already processing this type of premade NW in its line. The in line creation of this kind of product will give environmental impact reduction and product/process benefit in comparison with standard product.

Test and next steps

FAMECCANICA has installed a complete unit for nonwoven perforation.The unit consists of two rolls:

FAMECCANICA is working at the validation at full speed.