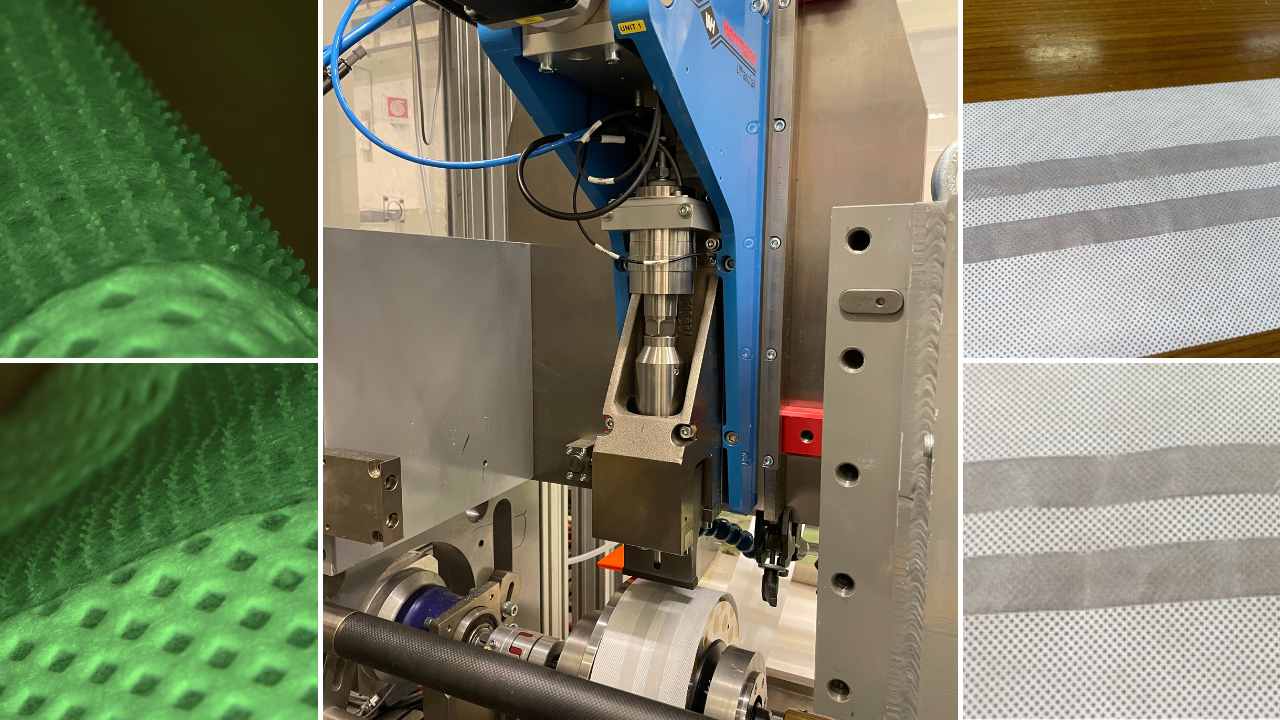

Fameccanica has marked yet another significant milestone in the Life ALL-IN R&D project. In fact, the company has successfully validated the 'In-Line Hook Forming' for Absorbent Hygiene Products, a breakthrough that eliminates the use of pre-made materials and promises to enhance machine efficiency.

The process

'In-Line Hook Forming' is a transformative manufacturing process that redefines how hook components for hygiene products are produced. Traditionally, these hook components were manufactured separately and then integrated into the product. However, Fameccanica has pioneered a new approach:

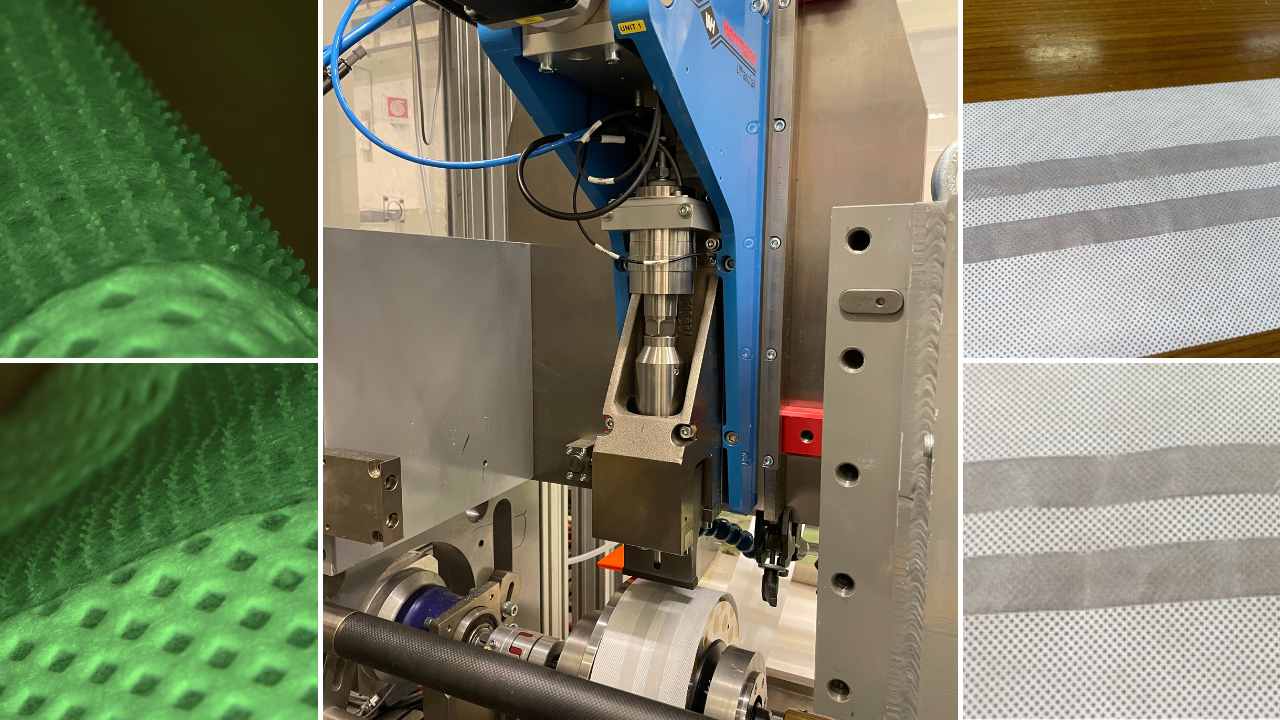

- US Bonding Process: The key to 'In-Line Hook Forming' lies in the US (Ultrasonic) bonding process. This process enables the creation of hooks by locally melting and shaping nonwoven (NW) material within the production line itself.

- Standard US Equipment: This innovative approach utilizes standard US equipment, with a customized sonotrode, to achieve the desired hook formation.

- Anvil Surface Design: The shape of the "hook" is determined by the pattern of holes on the anvil surface, allowing for precise customization.

Expected advantages

The validation of 'In-Line Hook Forming' brings several notable advantages to the table:

- Reduced Material Dependency: By eliminating the use of pre-made hook components, the process reduces material dependency and minimizes waste, aligning perfectly with sustainability goals.

- Enhanced Efficiency: 'In-Line Hook Forming' streamlines the manufacturing process by integrating hook formation seamlessly. This efficiency improvement not only reduces production costs but also enhances the overall output.

- Customization: The ability to define hook shapes through the anvil surface pattern offers customization possibilities that can meet specific product requirements, ensuring a tailored approach to hygiene product manufacturing.

If you are curious, contact us!

Back