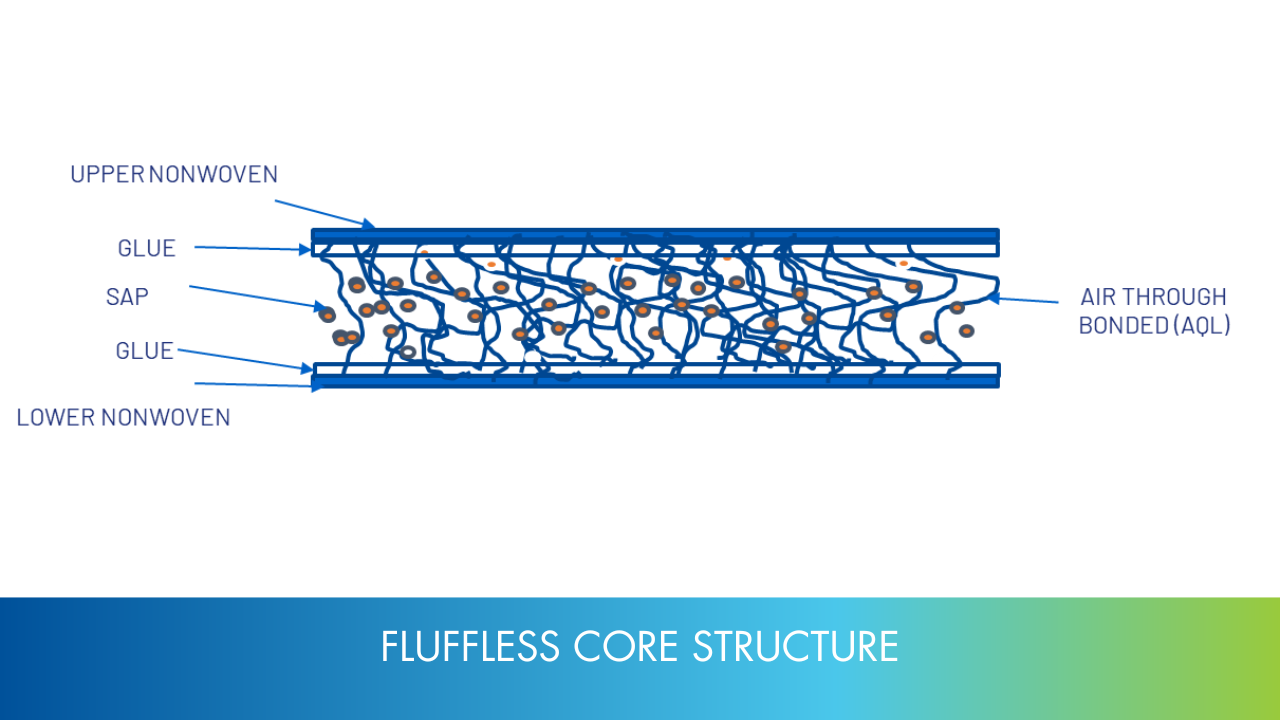

Fameccanica, coordinator of the LIFE ALL-IN project, has successfully validated the in-line creation of the Acquisition Layer for Air Through Bonded Material (ATBM) within the AHPs (Absorbent Hygiene Products) machines. This innovative approach eliminates the use of pre-made materials and promises to revolutionize the diaper manufacturing industry improving the machine efficiency.

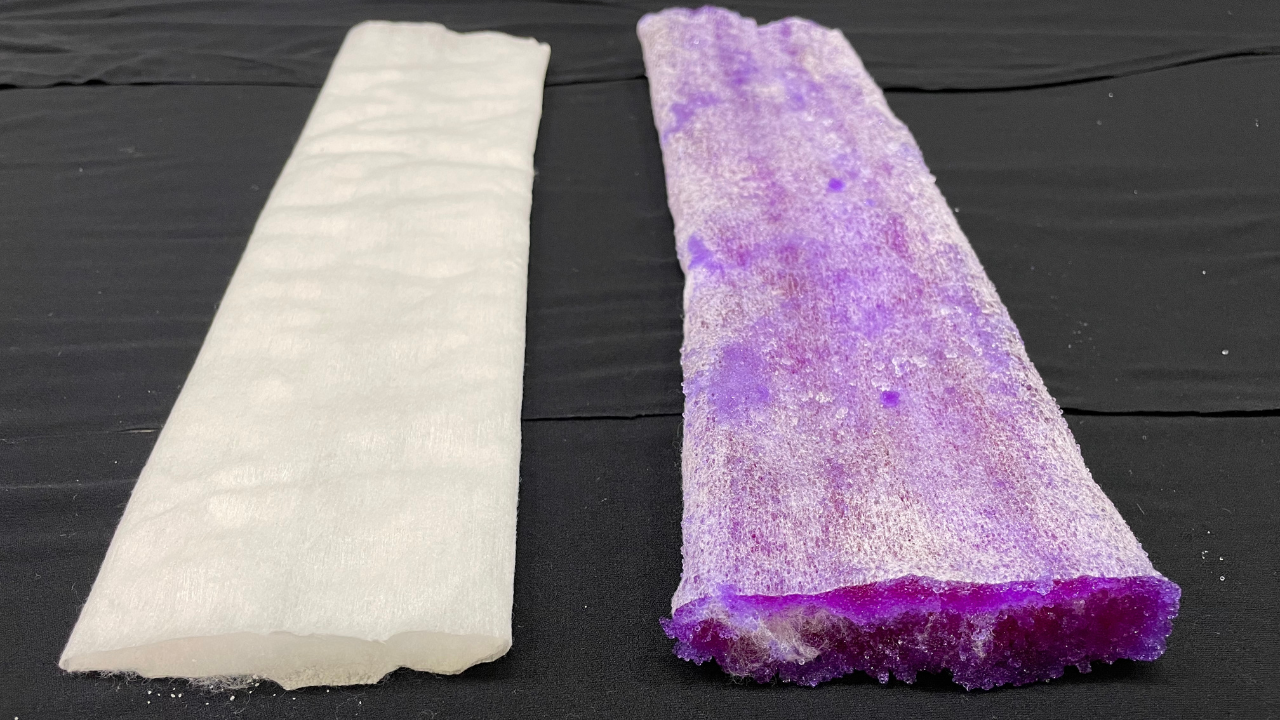

Fameccanica's strategic approach to in-line creation of the Acquisition Layer is a game-changer. The company aimed to develop a system that could seamlessly create this crucial layer with specific features, ultimately producing fluffless core products. This bold strategy represents a departure from conventional practices and underscores Fameccanica's commitment to innovation and sustainability.

The achievement of this milestone carries a multitude of advantages:

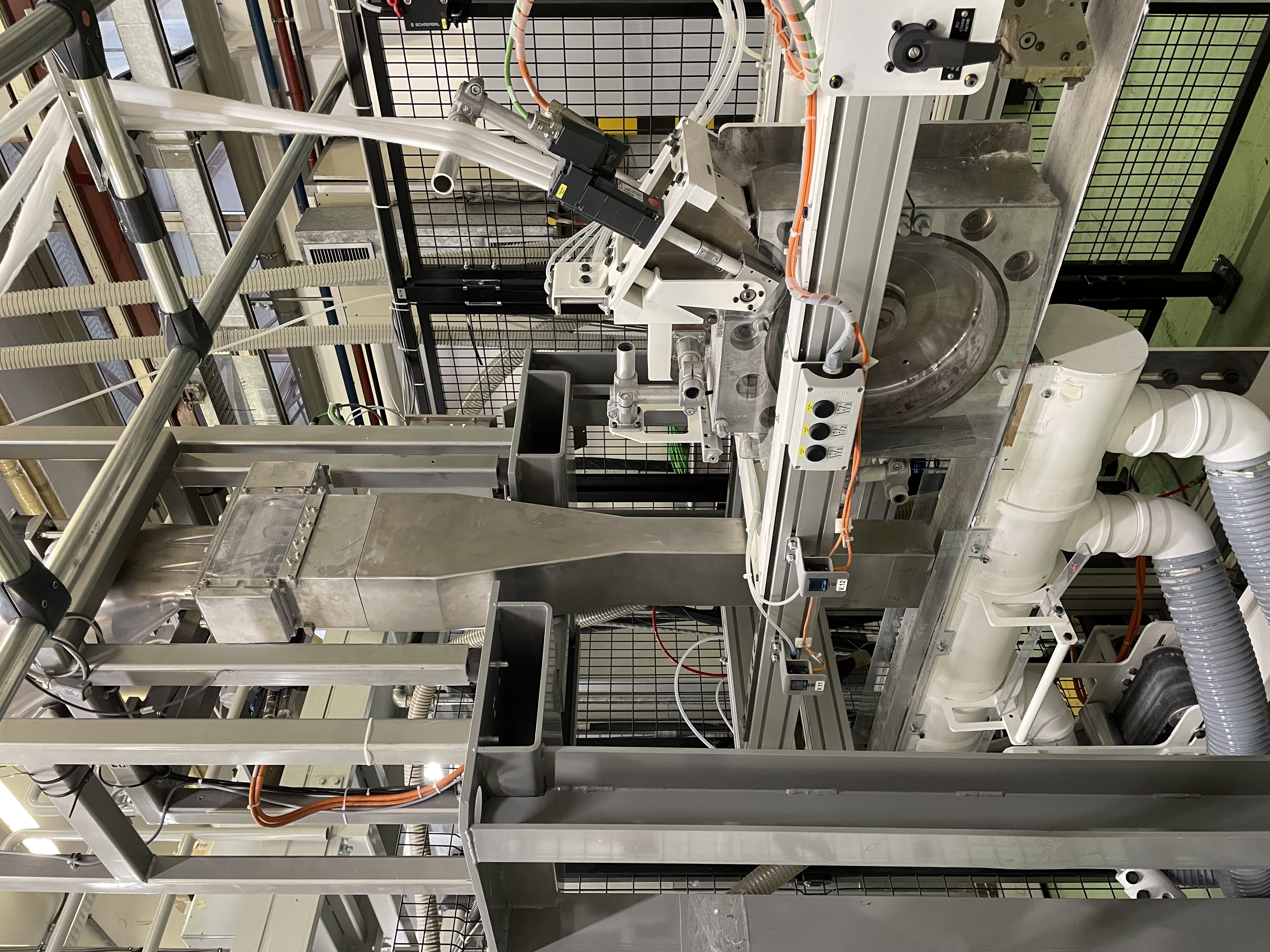

The results of the LIFE ALL-IN project milestone are nothing short of remarkable. Fameccanica has conducted extensive testing and validation in its state-of-the-art test lab, confirming the feasibility and effectiveness of in-line Acquisition Layer creation. Here are the key parameters and findings:

Fameccanica's achievement of in-line creation of the Acquisition Layer is a significant milestone not only for the company but for the entire diaper manufacturing industry. This innovative approach promises to reduce costs, optimize logistics, and enhance product quality and comfort, all while contributing to a more sustainable and eco-friendly manufacturing process. Fameccanica's dedication to pushing the boundaries of diaper production exemplifies its commitment to both innovation and environmental responsibility, setting a new standard for the industry. As the LIFE ALL-IN project continues to progress, we can look forward to even more groundbreaking advancements in the world of hygiene and diaper manufacturing.

If you are curious about this milestone reached, contact us!